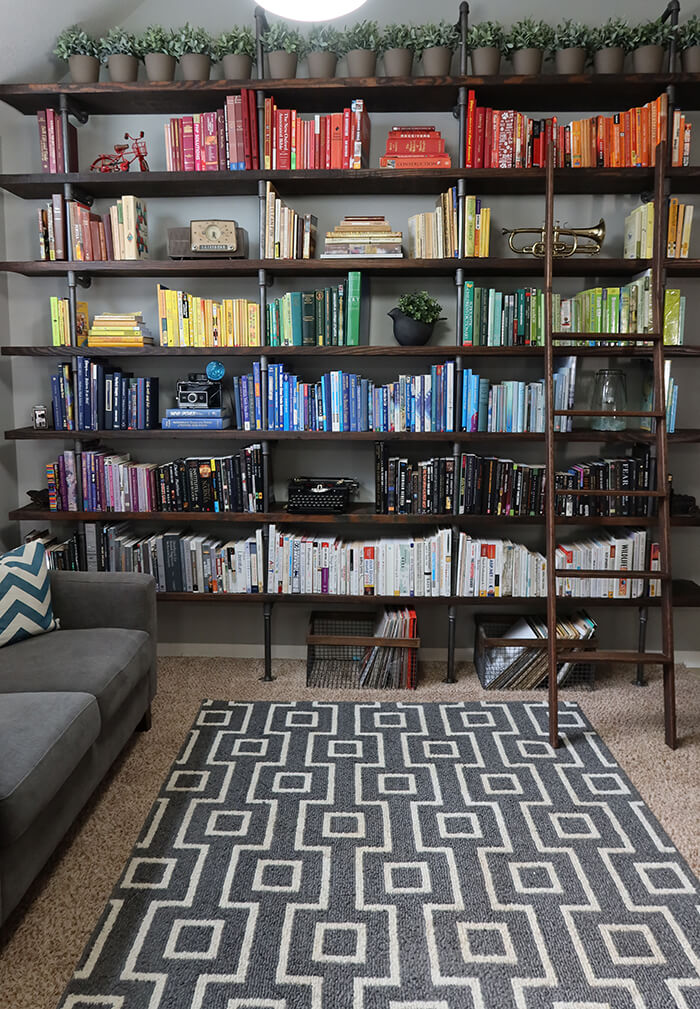

Creating a cozy home library was at the top of our must-have in our house list. We challenged ourselves to build a large wall of floor to ceiling pipe shelves to store all of our books. We made plans if you want to build them too!

Both Brent and I enjoy reading and liked the idea of having lots of shelves filled with books on display. We wanted lots of shelving but didn’t necessarily want to build a large conventional bookcase.

We decided on building the support system out of pipes. By going with an industrial design for our library shelves, we needed less tools and could piece it together over a few weekends but it still visually packs a big punch in the front of our house.

There is nothing better than a big blank canvas ready for a DIY project!

How to Build Large Industrial Pipe Shelves

Supplies:

- Our Pipe Shelves Plans

- (7) 2″ x 12″ x 10′ Pine Boards

- 2-1/4″ screws

- (32) 3/4″ x 12″ Long Black Pipe

- (28) 3/4″ x 6″ Short Pipe

- (4) 3/4″ x 2″ Nipple

- (4) 3/4″ x 3/4″ Coupling

- (32) 3/4″ x 3/4″ Elbow

- (28) 3/4″ x 3/4″ Tee

- (8) 3/4″ Flange

- Drill

- Kona Wood Stain

- 1-1/4-Inch Hole Saw

- Kreg Jig

- Kreg Face Clamp

FYI: This post contains an affiliate link to a product we used to make this project. Gray House Studio does receive commissions for sales from these links but at no extra cost to you. We appreciate you supporting this site. Read our privacy and disclosure policy. You can also easily shop our recommended products here.

Pipe Shelves Project Plans

When you purchase our DIY pipe shelves plans you get a PDF with a detailed materials list, a cut list, exact dimensions for each piece, and building instructions – all for only $10. We appreciate you supporting Gray House Studio! Join our e-mail list to get a 20% off coupon code.

Steps:

The day we bought the wood for the shelves was a doozy. I think I “worked out” harder on that day than I have in a long time. Helping Brent get those giant boards down off the shelf at the hardware store, into the truck, off the truck, into the backyard, up onto the platform to stain and then back into the garage was quite the job for my tiny little arms.

One criteria Brent had for the shelves was he wanted to use thick boards. He decided on using seven 2″ X 12″s in 10′ lengths. The reasoning behind this was we wanted the shelves to be sturdy and substantial in both functionality and appearance.

This is the centerpiece of the room so we really wanted to build something that would grab your attention as soon as you walk in our door and dinky little shelves just wouldn’t cut it.

The other element to the shelves were the pipes and fittings that would run through the boards.

The pipes were kind of gross when we got them (see photo above). They are coated so they don’t rust but since we were using the pipes and fittings indoors we had to spend a lot of time cleaning them.

It was a tedious task that consisted of wiping down roughly 150+ pieces of pipe with a paper towel and a little bit of paint thinner.

1 | We stained each board using the same stain as our nook wood plank wall, Kona wood stain.

2 | After I stained the board, Brent measured and marked where he would need to drill the holes so the pipes would go through the board.

He drew up all the plans himself and I was pretty impressed because each calculation and measurement had to be precise to ensure that every board would be same distance from the wall and line up with each other so the pipes could run through all them.

You can find the exact measurements in our DIY pipe shelves plans.

3 | Next he used a hole saw attached to his drill and drilled four holes into each board.

4 | Once Brent drilled the holes, there were some areas exposed that had not been stained so I filled in those spots with stain to achieve a seamless look.

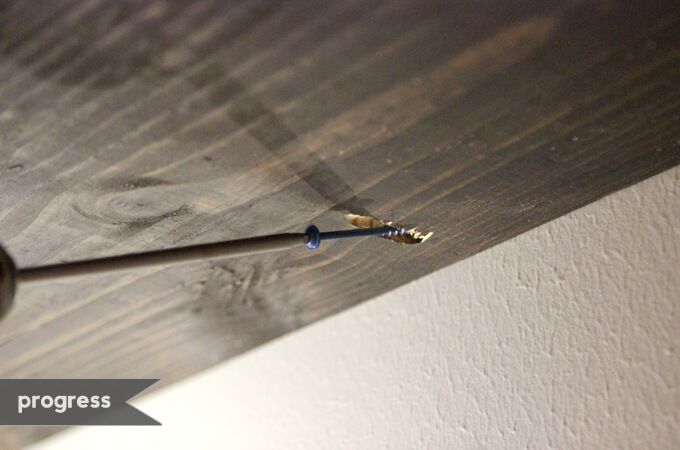

5 | He used a Kreg Jig and Kreg face clamp to drill four pocket holes that were measured to match the stud layout in that wall.

6 | We checked and double checked that each board was straight using our level.

7 | After each board was level we secured the board to the wall by screwing it into studs through the pocket holes.

For the bottom half of the shelves this was done on the bottom of the board and for the top half of the boards this was done on the top of the boards so that the holes in the boards would not be visible.

8 | We built the pipe shelves board by board adding the next row of pipes as we went up the wall.

We started by putting the 3/4″ flange pieces at the bottom of each of our pipes. This piece will eventually also go at the very top where it connects into the wall at the top.

This was our progress about half way. The photos below show closer up how the boards and pipes fit together.

These are the pieces of pipe we used to assemble the shelves:

- (32) 3/4″ x 12″ Long Black Pipe

- (28) 3/4″ x 6″ Short Pipe

- (4) 3/4″ x 2″ Nipple

- (4) 3/4″ x 3/4″ Coupling

- (32) 3/4″ x 3/4″ Elbow

- (28) 3/4″ x 3/4″ Tee

Get the detailed instructions for building and assembling the pipes for the DIY pipe shelves.

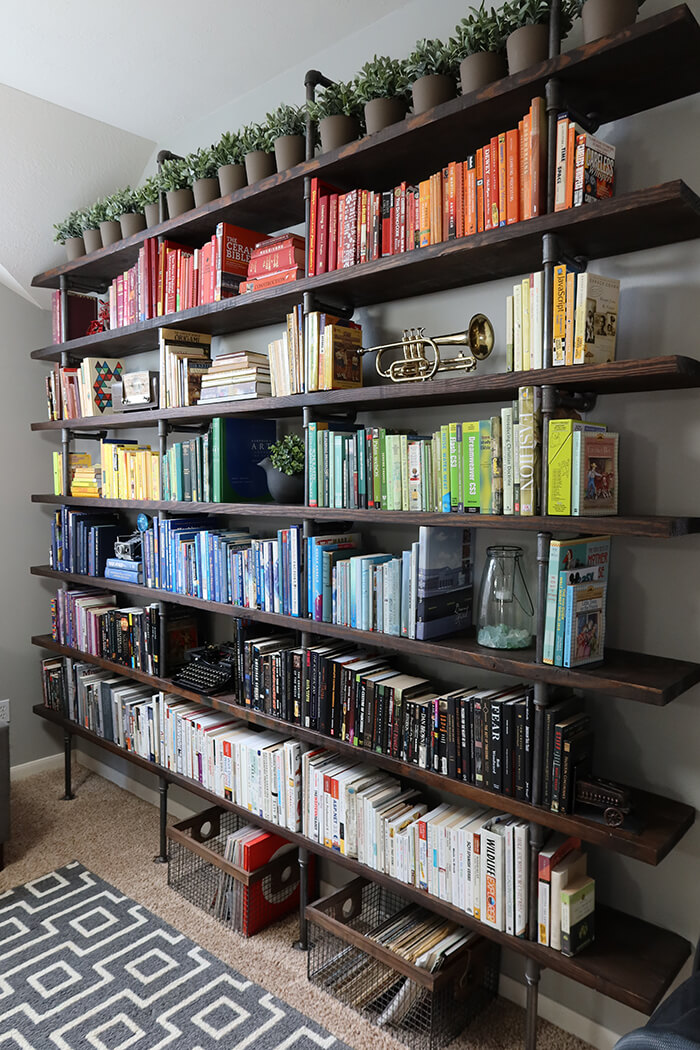

9 | After our DIY industrial shelves were installed, it was time to arrange all of our books and vintage pieces. It took me awhile to style the shelves and to be honest I will probably restyle them several more times.

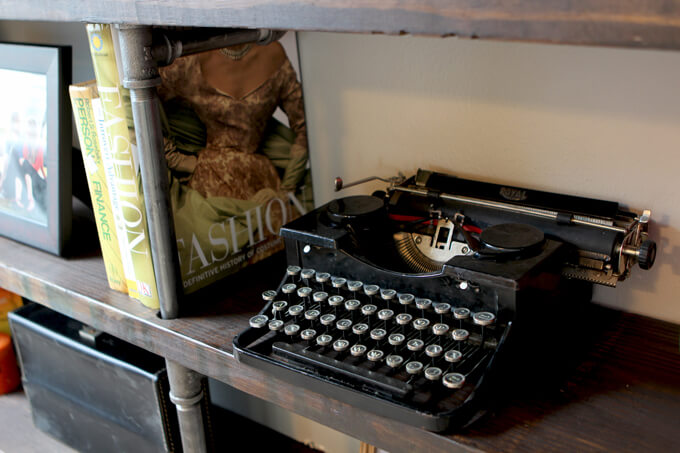

Our book collections combined were not enough to fill up all the shelves so we added some really cool antique items that Brent has collected over the years like this cool radio and typewriter.

I love old family photographs so I also wanted to display some of our grandparents in their younger years as well. Brent also built a stands to showcase a few records from his collection.

We are so happy with how our DIY industrial shelves turned out. They really add the wow factor when you walk in our door that we were looking for. Of course one project leads to another and now I am daydreaming about replacing that carpet with wood floors because that would really make the room cozy and make the industrial look of the shelves make more sense.

Featured in Better Homes and Gardens Magazine

Our DIY pipe shelves project was featured in the October 2015 issue of Better Homes and Gardens.

After staining the shelves did you add a polyurethane too coat? Love these shelves. So beautiful!

HI-Love your shelves! We will probably build similar. I appreciated the comment about where to order the pipes/fittings online.

How did you anchor the shelves to the wall?

I’m looking at the plans… just curious… was it SUPER expensive? i’m online and it looks pricey.

If I remember correct it cost about $500 which sounds expensive but considering it is 10ft by 10ft we felt like it was worth it.

Do you know if cleaning the pipes with paint thinner is enough to keep them from rusting? They don’t have to be sprayed with anything right? I have all the boards stained & ready, but need to clean pipes before I can assemble, & I read something online that said pipe would rust indoor or out as long as it is exposed to water/air/oxidation.

Have you had any problems or concerns about it?

It has been about 4 years since we install our pipe shelves and so far they look the same as the day we installed them. We haven’t seen any rust so far so that is a good sign. 🙂

Hi! love the shelves! I am wondering where you found the baskets underneath that hold the vinyls! They are just what I have been looking for:)

Thanks Holly! We purchased the baskets at HomeGoods. They are awesome! 🙂

-Courtney

Great job, looks awesome. What size pipe and fittings did you use please? Looks like 3/4” ?

Thanks Steve! That is correct, we used 3/4″ black pipe. – Brent

Are your shelves sitting on carpet or wood flooring? I have seen other posts and they are always on hardwood floors and are screwed down. I want to do these in my son’s room but it is carpeted, and not sure how I feel about drilling holes in the carpet if that is necessary for support and stability.

The shelves are very cool and thanks for posting the plans. I’m skeptical that as built they are sturdy enough. Did you do any sort of analysis to determine if the pipe structure can support seven fully loaded shelves without any buckling?

If I were to build these I think I would add double-up the two outer columns to add additional structural support. It might be over-engineered, but the entire structure could be loaded with a thousand pounds of books or more and better to err or the side of safety.

We were also concerned about potential problems the total weight of seven shelves worth of books might impose. We didn’t have a great way to do any formal analysis but we did take extra precaution to make sure we wouldn’t run into any problems. We anchored each shelf to wall studs using pocket screws and are happy to say we have not had any issues. We even have a ladder that leans against the shelving unit that is very comfortable to stand on.

-Brent

THANK YOU for sharing the plans to these shelves!! We turned our formal living room into an office for my husband and have desperately needed bookshelves (we went from a house with 2 huge builtin bookshelves/cabinets to a house w/zero and not a ton of wall space for them either), but couldn’t bring ourselves to spring for the $2k+ for the bookselves that matched his desk. These are going to look fantastic in the space we have for them and the approximate price tag doesn’t make me feel sick to my stomach. I promise to post a photo when we’re done 🙂 (it might be months from now but tomorrow I will start the search for the black pipe fittings around here!)

ps: saw this on Yahoo, which then pointed to BHG, then your blog 🙂 (in case that matters)

Aw, thanks so much M L! We know the feeling. We had a limited budget for shelves which is why this style works so well. It looks great but you don’t have to stress over the price. Ha, yes you might want to get a jump start on finding all those pipes because we learned from experience that it can take awhile. 🙂 We also learned that you should be able to get the pipes and fittings even cheaper (and quicker) if you order them online in bulk. We can’t wait to see your shelves when you are finished. I am sure they will look fantastic. Thanks so much for taking the time to stop by our blog and share how you found us.

-Courtney

We ended up buying all our pipes/fittings at supplyhouse.com; *way* more cost effective than anywhere local to us. We ended up making a few modifications (6 shelves instead of 7, did a wipe on varnish to help the wood not dry out too much in the triple digit summers (even w/AC, its still pretty dry here)) and are going to create a lift-up door for the bottom row, plus add cleats to the two bottom rows of shelves, just for the extra strength. We’ve got the shelves up, and once we do the doors, I’ll share a photo. Excellent instructions, btw! Between those and the photos on the blog, we were able to easily (after hours of cleaning the pipes up and staining boards, lol) put the shelves together. 🙂 Photos before Christmas (fingers crossed!)

Wow! Great job! You guys know how to build some shelves!!! I’m going to try these in my house; I’ve been looking for ideas, but everything I found (including one called a ‘goliath’ bookshelf- ha!) were just so pathetically flimsy. I saw yours in BH&G, and thought ‘This is what I’m talkin’ about!’

Thanks for taking the time to document and share your great idea! ????

Thanks Martha! That is a great compliment. It made our day because one of our goals with the shelves was to build them nice and sturdy both in appearance and functionality. We’re excited you are going to make your own and appreciate you taking the time to stop by our blog.

-Courtney

Do you have the plans for your shelves? They are great and I can’t wait to try and make them.

Hi Jen, thanks so much! Yes, we do have plans for our shelves and we will finally be posting them next Monday. We are so excited you will be making your own.

– Courtney

I love this and have been planning on something like this is my living room. I can’t wait to see the plans. I’m a big fan!

Thanks Marie! So exciting to hear you have similar plans for your living room! Keep a look out, we will be posting the plans soon.

The shelves look awesome – great work!

Thanks Chelsea!

Hello! I love this bookcase and want to make one myself. Do you have the planning details for me to purchase? I clicked on the link but it is currently unavailable. Please let me know! Many thanks. Serena